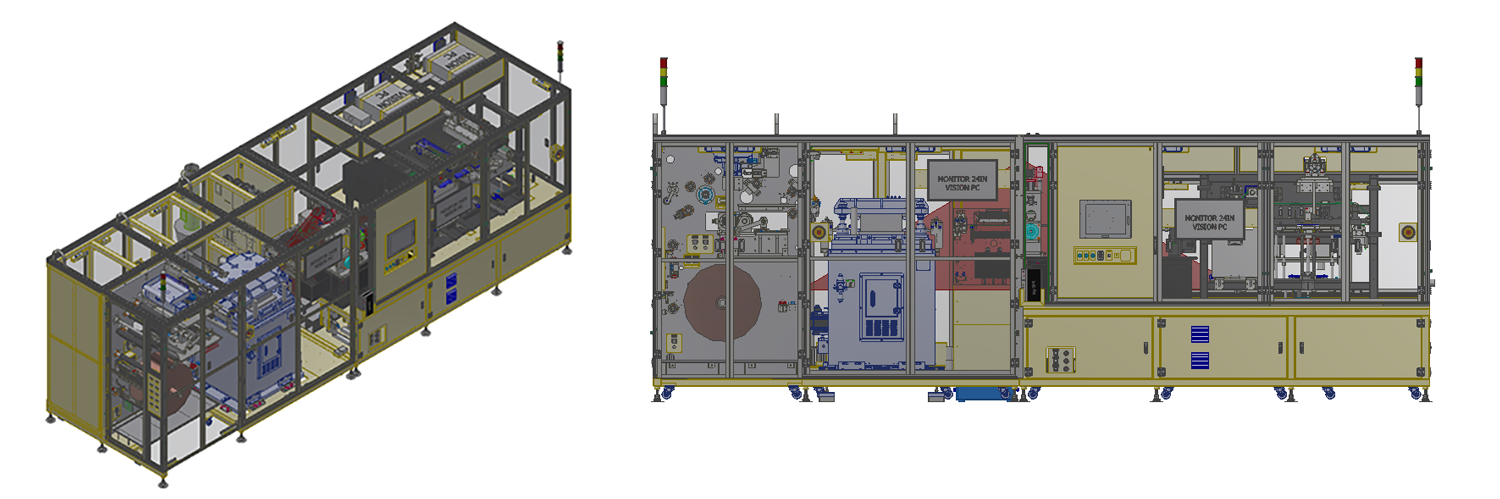

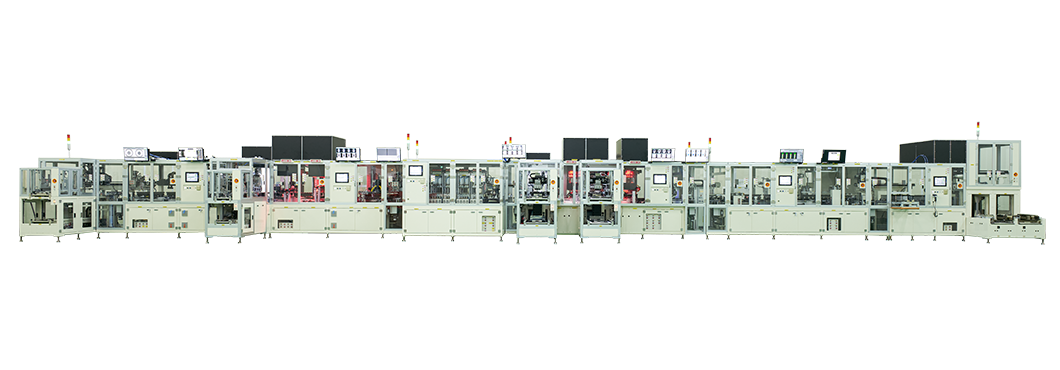

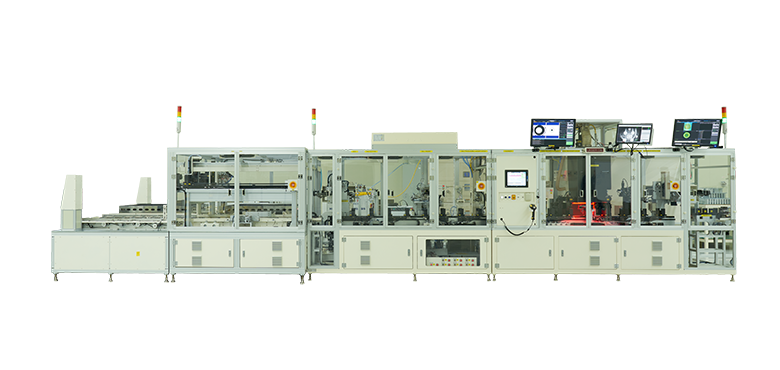

Equipment that processes electrode materials coated with active material on both sides of Al/Cu foil. Using a die, the material is notched into the required electrode shape. A vision inspection system then checks the notched electrodes to distinguish between good and defective products. Afterward, the inspected electrodes are discharged from the equipment.

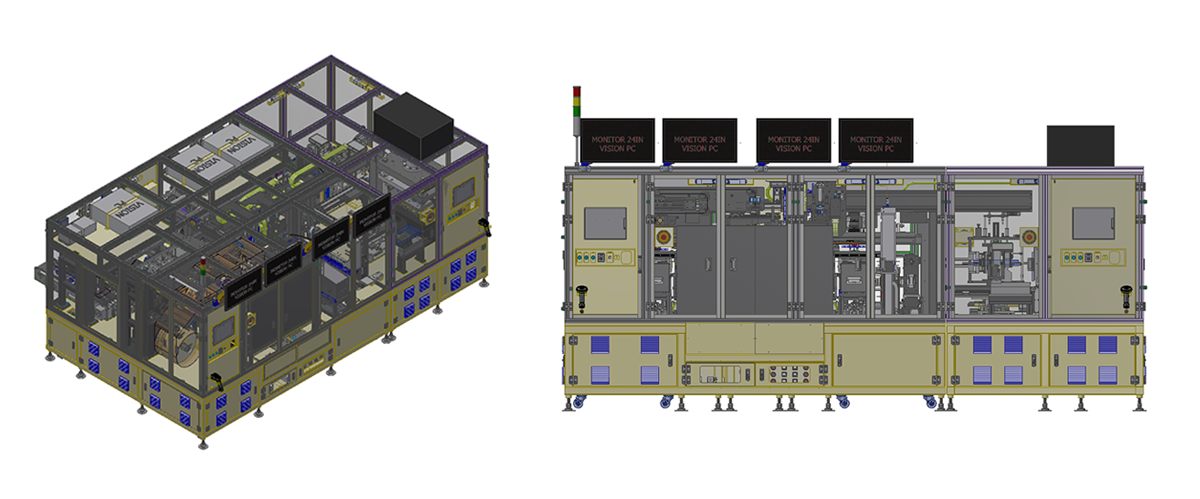

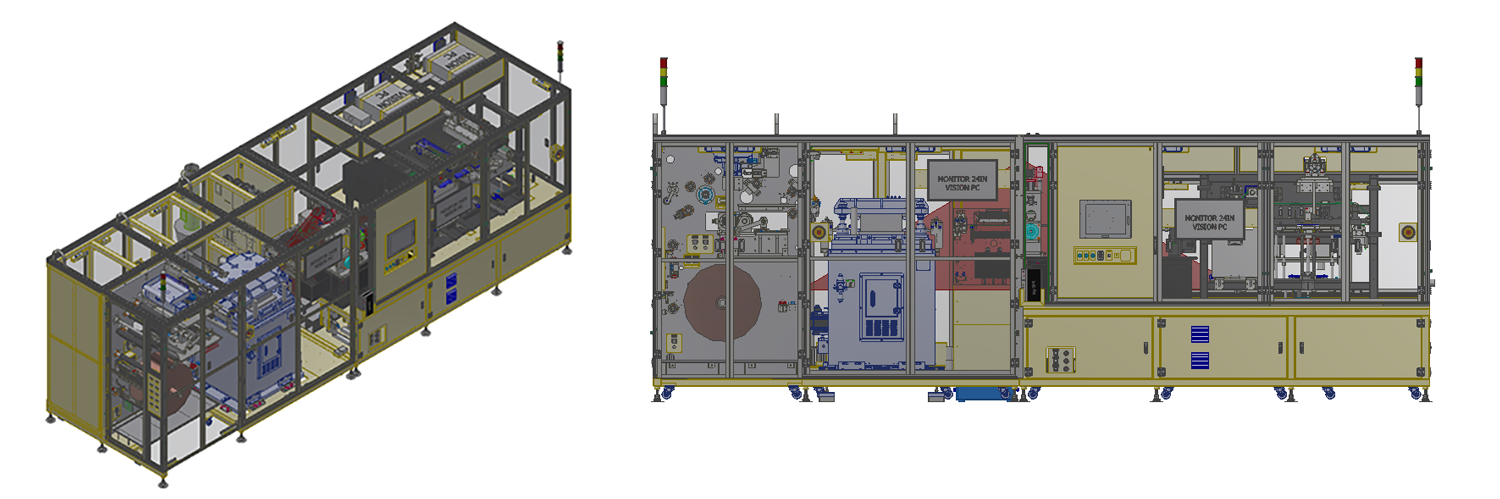

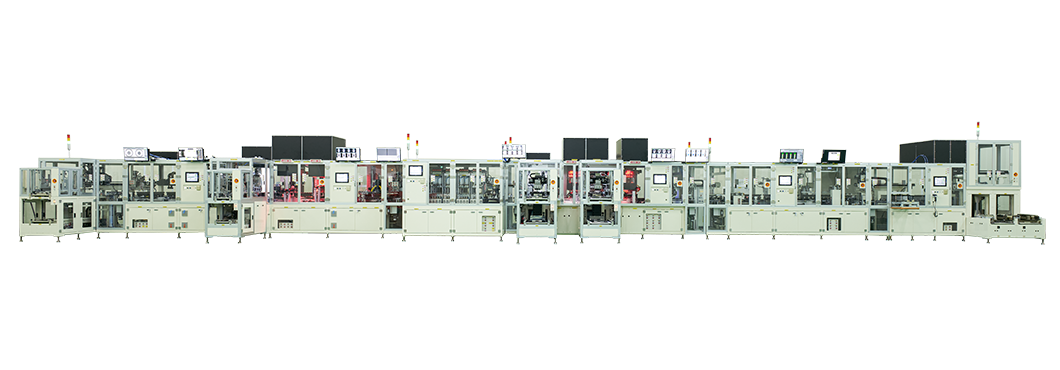

Equipment designed to receive notched anode and cathode electrodes from the previous process, supplied either in roll or magazine form. After loading each electrode, a separator is wrapped around the electrodes in a zig-zag form through sequential stacking. The process is completed with winding and taping, after which the assembled unit is discharged.

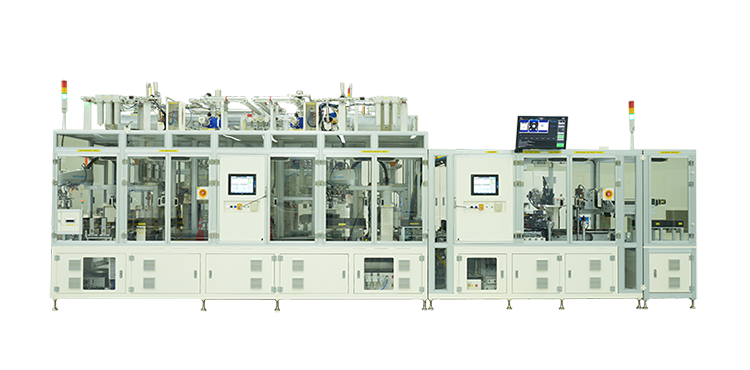

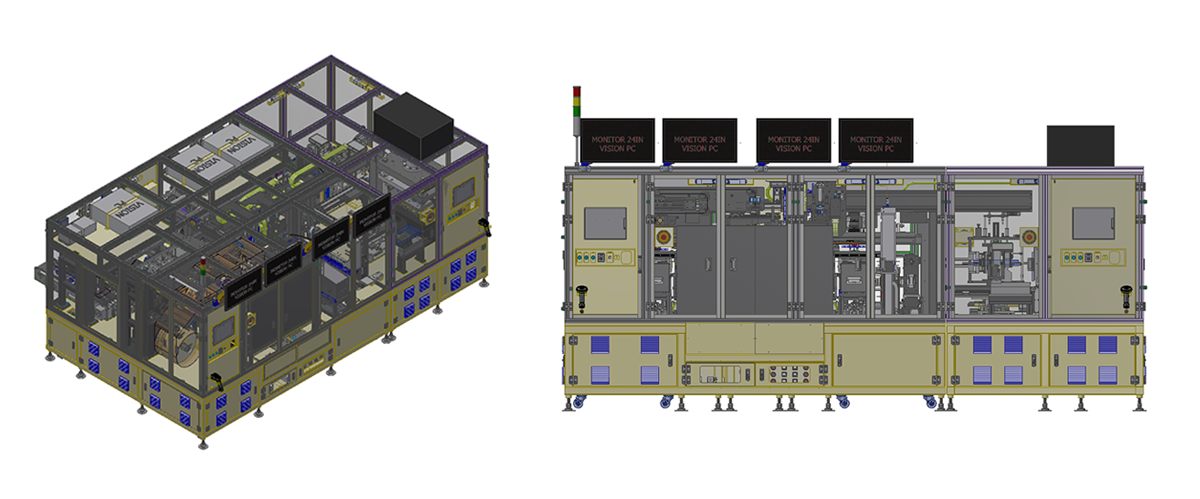

Automated equipment for ultrasonic welding of the anode and cathode sections of the jelly roll, followed by inspection of the welded areas.

Automated equipment that welds the pre-welded jelly roll and cap assembly using ultrasonic and laser and then attaches the insulator tape.

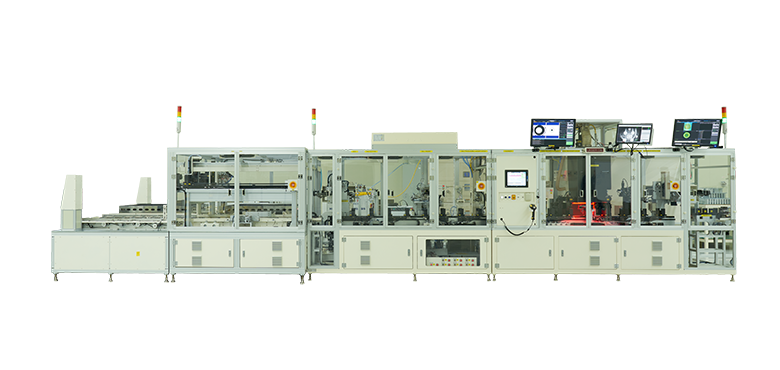

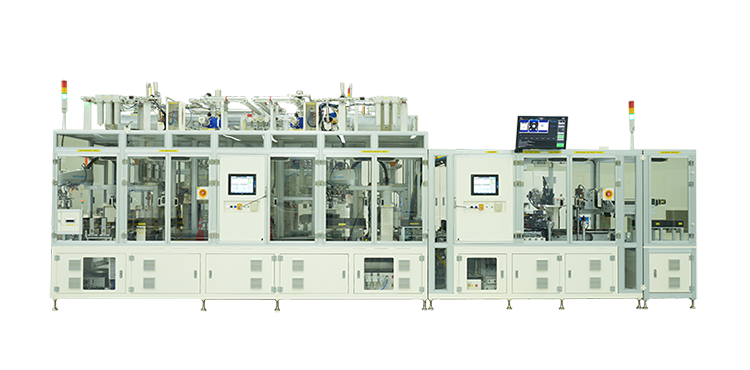

Automated equipment that inserts the the jelly roll with cap assembly attached into a can, welds the can and cap assembly with a laser, and then performs welding bead and leak inspection.

Automated equipment that quantitatively injects electrolyte into the battery cell and then inserts a seal cap into the injection port.

Automated equipment that seals the battery injection port with a seal ball to prevent electrolyte leakage, then cover it with a seal pin, and performs laser welding.

Automated equipment that welds the vent onto the cap plate, performs leak inspection, C.C welding, flatness inspection, terminal resistance inspection, and C.C gap inspection.

433-15, Sandong-ro, Eumbong-myeon, Asan-si, Chungcheongnam-do, Korea TEL.

82-41-421-5000

TEL.

82-41-421-5000 FAX. 82-41-421-5099

FAX. 82-41-421-5099

117-26, 2gongdan-5ro, jiksan-eup, seobuk-gu, Cheonan-si, Chungnam, Korea TEL.

82-41-410-2000

TEL.

82-41-410-2000 FAX. 82-41-410-2099

FAX. 82-41-410-2099

16, Waryong-gil, Seonghwan-eup, Seobuk-gu, Cheonan-si, Chungcheongnam-do, Korea TEL. 82-41-411-2600

TEL. 82-41-411-2600 FAX. 82-41-411-2599

FAX. 82-41-411-2599

46, Magokjungang 8-ro 5-gil, Gangseo-gu, Seoul, Korea TEL. 82-2-6942-6700

TEL. 82-2-6942-6700 FAX. 82-2-6942-6799

FAX. 82-2-6942-6799

Copyright(C) JASTECH LTD. All Rights Reserved.

Copyright(C) JASTECH LTD. All Rights Reserved.